The main uses of engineering plastic bearings on ships are structural parts and transmission parts, which have outstanding performances such as high wear resistance, corrosion resistance, self-lubrication, maintenance-free, low water absorption, chemical resistance, low friction coefficient, etc. and are solid and reliable. Compared with traditional metal bearings, engineering plastic bearings also have the advantages of light weight, low noise, long life and low cost, and can operate normally in harsh environments.

Engineering plastic bearings

Stern bearing:The stern bearings of ships used to be mainly made of wood, hard rubber or metal. The manufacturing process is complicated, the time period is long, the cost is high, and regular maintenance is required later. Wood and hard rubber are lubricated with water, and metal materials are lubricated with oil. The use of engineering plastic stern bearings has the advantages of simple manufacturing process, low cost, long service life, and no need for lubrication, etc., effectively making up for the deficiencies of traditional processes.

Auxiliary machine bearings:Marine auxiliary machinery bearings used to be made of copper alloy materials before. They are used in large quantities. The manufacturing process is complicated and not easy to install. In addition, they are easy to bite or wear on the journal during use. Use engineering plastic auxiliary machine bearings, low noise, wear resistance, self-lubrication, corrosion resistance, etc. during use, and can save a lot of non-ferrous metals, simplify the production process, extend the service life and improve efficiency.

Rudder bearing:The rudder bearing of the ship is made of engineering plastic PEEK material, which is made of cast molding. The process is simple, easy to install, and low noise.

Piston ring:The main materials of plastic piston rings used on ships are special plastics such as PAI and PEI. They are mainly used for seawater pumps, freshwater pumps, oil circulation pumps and air compressors operating in normal temperature environments.

gear:The engineering plastic gears used on ships are mostly special engineering plastics, such as PEEK, PEI, PAI and other materials, which have high rigidity and fatigue resistance, outstanding wear resistance, excellent heat resistance, low friction coefficient, and low water absorption The advantages are simple production and easy installation.

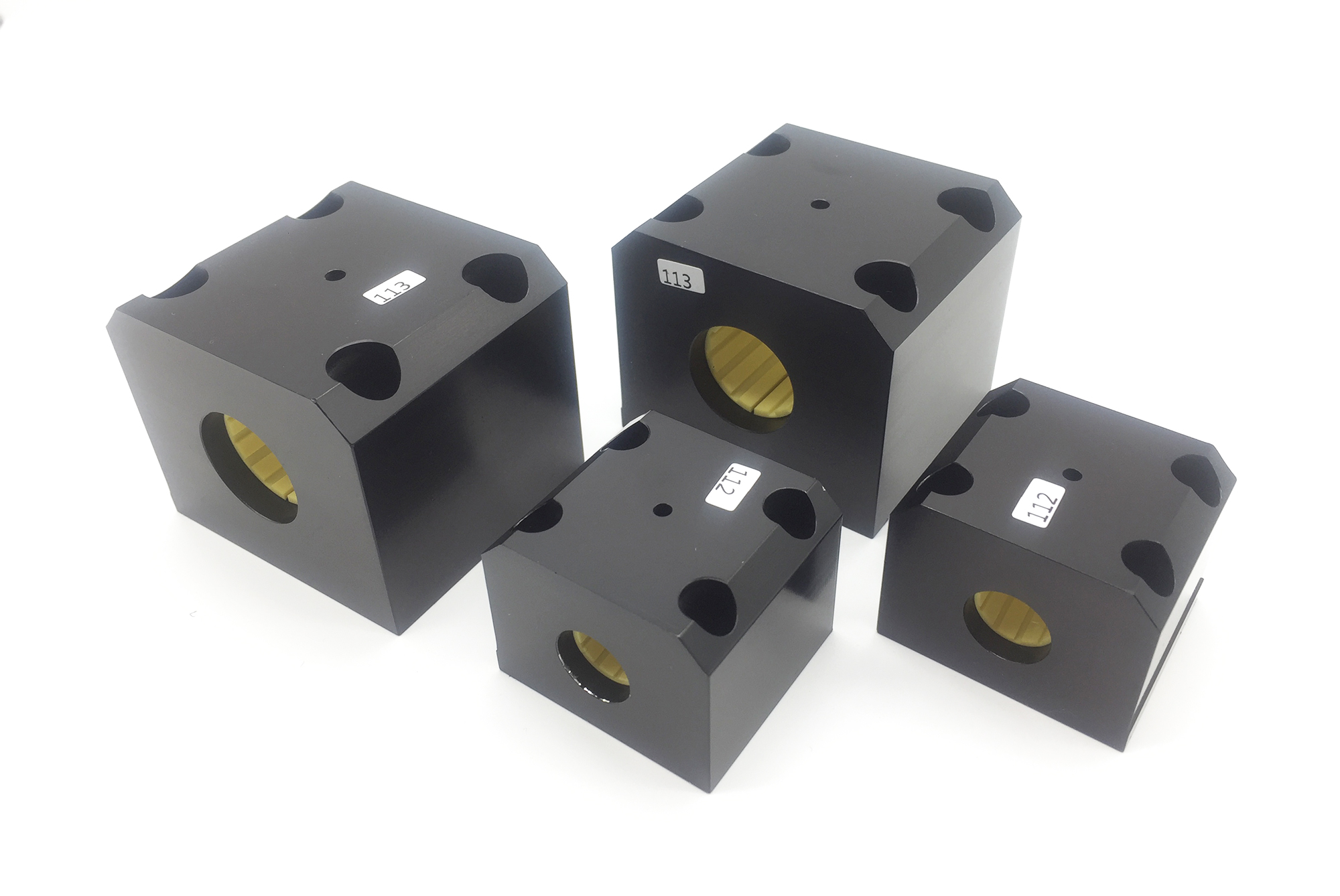

Slider:Most of the sliders used on ships are made of metallic copper materials before, which are easy to be corroded, noisy, and require oil lubrication and other limited performances, while the engineering plastic slider bearings made of high-strength (high hardness) PEEK have low noise , Low friction, corrosion resistance and other advantages, can effectively replace metal sliders.

Advantages of engineering plastic bearings:

Engineering plastic bearings are an important part of contemporary machinery and equipment. The main function is to support the mechanical rotating body and reduce the friction coefficient during its movement. Performance: Long service life, easy installation, corrosion resistance, wear resistance, self-lubrication, low noise, low water absorption, light weight, chemical resistance, oxidation resistance, low cost and other properties.

Engineering plastic bearing classification:

Plastic plain bearings:

Sliding bearings have no inner and outer rings and no rolling elements, and are generally made of wear-resistant materials. Commonly used for low-speed, light-load and lubricating oil, and mechanically rotating parts that are difficult to maintain.

Plastic joint bearings:

The sliding contact surface of the joint bearing is spherical, which is mainly suitable for swinging motion, tilting motion and rotating motion.

Plastic rolling bearings:

Rolling bearings are divided into radial bearings and thrust bearings according to the different load directions or nominal contact angles they can bear. The radial contact bearing is a radial bearing with a nominal contact angle of 0, and the radial angular contact bearing is a radial bearing with a nominal contact angle greater than 0 to 45. The axial contact bearing is a thrust bearing with a nominal contact angle of 90, and the thrust angular contact bearing is a thrust bearing with a nominal contact angle greater than 45 but less than 90.

-----This article comes from other websites